Medium Voltage Cable Splicing

In high-power commercial and industrial settings, electrical reliability isn’t optional—it’s essential. At the heart of this reliability lies a critical yet often overlooked process: medium voltage cable splicing. Whether you’re powering a manufacturing facility, solar farm, or multi-building campus, the integrity of your cable splices directly affects your system’s performance, efficiency, and safety.

At ASAP Electric, we specialize in safe, code-compliant medium voltage splicing for clients in Stockton, Manteca, Tracy, and across California’s Central Valley. In this article, we break down what medium voltage splicing involves, key techniques, safety standards, and why experience makes all the difference.

🔌 What Is Medium Voltage Cable Splicing?

Unlike low-voltage wiring, MV splicing involves higher electrical stress, more complex insulation systems, and strict code compliance. Faulty MV splices can cause:

- Voltage drops

- Partial discharge and arc faults

- Equipment failure or fire

- Dangerous working conditions

🛠️ Key Techniques Used in Medium Voltage Cable Splicing

Different splicing techniques are used depending on the system’s specifications, environmental conditions, and application. Here are the most common:

1. Heat Shrink Splicing

- Uses a thermoplastic sleeve that shrinks when heat is applied.

- Creates a tight, sealed connection with high mechanical and moisture resistance.

- Common in outdoor or underground applications.

2. Cold Shrink Splicing

- Made from pre-stretched elastomeric tubes that shrink when the core is removed.

- Requires no open flame or heat, reducing safety risks.

- Excellent for tight spaces and environments with moisture or chemical exposure.

3. Tape-Based Splicing

- Involves manual wrapping of insulation and conductive tape.

- Less common in modern MV applications but may be used for temporary fixes.

- Requires high skill to apply evenly and safely.

4. Pre-Molded or Modular Joints

- Factory-made components designed for quick, uniform installation.

- Provide consistency, reduced labor time, and lower risk of human error.

- Ideal for high-reliability installations and long-term performance.

⚠️ Safety Standards and Compliance Requirements

Medium voltage systems operate under high energy conditions, requiring strict adherence to national and local safety codes.

The standards we follow include:

- IEEE 404 – Standard for cable jointing in MV applications

- OSHA 29 CFR 1910.269 – Electrical safety for utility and industrial systems

- NFPA 70E – Electrical safety in the workplace

- California CSLB C-10 License Compliance – Required for electrical contractors

Safety Considerations:

- Arc Flash Protection: Improper splicing can cause dangerous arc flashes. Proper insulation and testing are essential.

- Grounding and Shielding: Prevents transient voltages and ensures personnel safety.

- Moisture Sealing: Critical for preventing degradation, especially in underground or outdoor environments.

✅ Best Practices for Reliable Medium Voltage Splicing

The quality of a splice determines the lifespan and reliability of the entire electrical system. Here’s how ASAP Electric ensures long-lasting splices:

✔️ Use of High-Quality Materials

We only use components rated for medium voltage, including:

- Insulation with high dielectric strength

- Moisture-resistant and UV-stable jackets

- Corrosion-resistant connectors and shields

✔️ Environmental Preparation

Before splicing, we assess:

- Humidity and moisture exposure

- Soil corrosiveness (for underground cables)

- Temperature fluctuations and chemical exposure

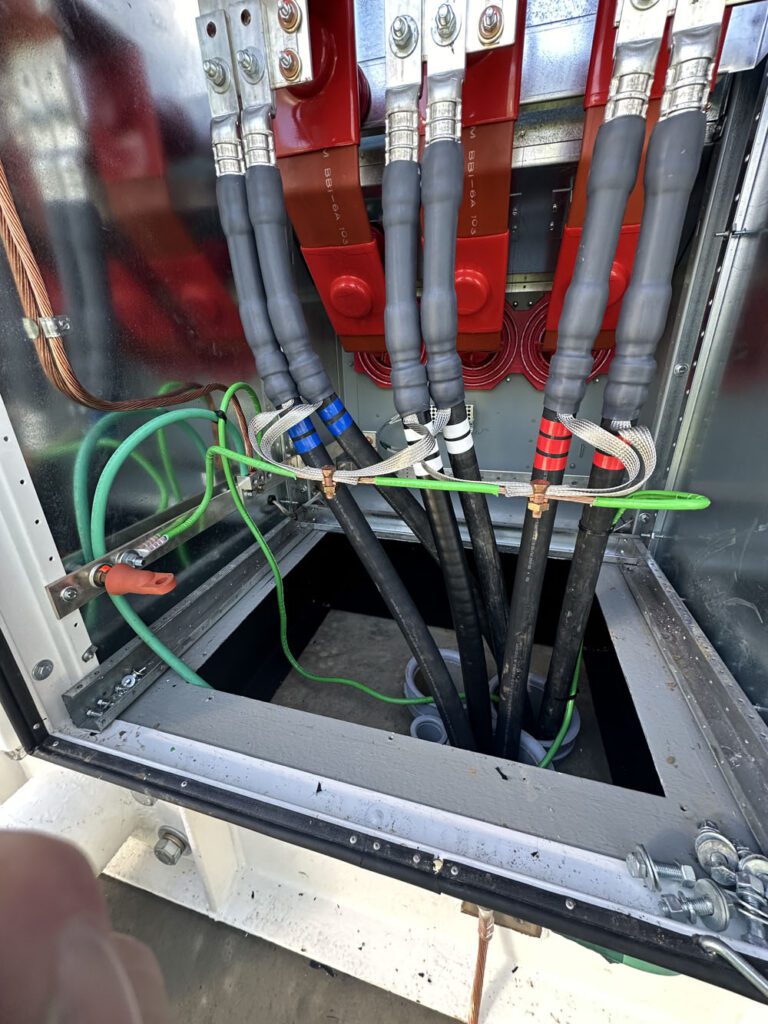

✔️ Expert Installation Techniques

Our certified technicians follow a multi-step procedure:

- Strip and prepare conductors without nicks or damage

- Precisely align conductors and secure with crimp connectors or compression fittings

- Apply insulation and shielding layers with exact spacing and overlap

- Seal with cold or heat shrink tubing per manufacturer and code specs

✔️ Post-Installation Testing

Every splice is tested using:

- Insulation Resistance Testing (Megger)

- Hi-Pot (High Potential) Testing

- Partial Discharge Testing (when required)

These ensure the splice meets operating voltage requirements and performs safely under load.

🧰 Why Experience Matters: Don’t DIY Your MV Splice

Unlike low-voltage electrical work, medium voltage splicing is not a DIY project. Mistakes can cause catastrophic failures, violate code, and void warranties or insurance policies.

⚡ Why Choose ASAP Electric for Medium Voltage Cable Splicing?

We’re not just general electricians—we’re your licensed C-10 electrical contractor with extensive experience in high-voltage and medium-voltage systems. Here’s what sets us apart:

🔹 Local Expertise

We serve clients across Stockton, Manteca, Tracy, and the Central Valley, and we understand the specific environmental and permitting requirements for the region.

🔹 Licensed and Certified Team

Our splicing technicians are trained in the latest MV techniques, safety protocols, and compliance requirements.

🔹 Turnkey Project Support

From consultation and design to execution and post-installation testing, we manage every step with precision.

🔹 Commitment to Safety and Quality

We go beyond compliance—our splicing methods are designed to reduce maintenance, downtime, and long-term risk.

Frequently Asked Questions

Medium voltage typically ranges from 1 kV to 35 kV. Anything within this range should follow MV-specific splicing standards.

With correct materials and installation, MV splices can last 20–30 years or more, depending on environmental conditions.

Yes—cold shrink is often safer and more convenient, especially in hazardous or confined environments. The best choice depends on the application.

Yes. ASAP Electric provides 24/7 emergency service for MV splicing and power restoration projects.

Ready to schedule your project?

If your commercial or industrial facility needs expert medium voltage cable splicing, trust the professionals at ASAP Electric.

- Call: (209) 473-8555

- Email: info@asapelectric209.com

- Service Area: Stockton, Manteca, Tracy, Turlock and the 209 region

- Licensed. Certified. Local.